Looking to upgrade your kitchen flooring to something durable, easy to clean, and stylish? Consider installing a resin floor!

We will discuss the benefits of choosing a resin floor for your kitchen, the different types of resin floors available, the steps involved in the installation process, the tools and materials you will need, and maintenance tips to keep your resin floor looking pristine.

Discover more about this modern flooring option for your kitchen.

What Is A Resin Floor?

A resin floor is a contemporary flooring solution known for its durability, seamless design, and aesthetic appeal.

These floors have gained popularity in both residential and high-traffic commercial settings due to their ability to withstand heavy use and maintain their visual appeal over time.

One of the key advantages of resin flooring is its waterproof nature, making it an excellent choice for areas prone to spills or moisture.

The seamless application of resin floors creates a sleek and modern look, enhancing the overall design and aesthetics of a space.

The customizable nature of resin floors allows for endless design possibilities, from vibrant colors to luxurious finishes, making them a versatile and stylish choice for any interior.

Discover: Is Epoxy Flooring Good For Living Room

Why Choose A Resin Floor For Your Kitchen?

Opting for a resin floor in your kitchen offers a blend of durability, easy maintenance, and a stylish appearance that can elevate your home’s aesthetic.

The durability of resin floors makes them ideal for high-traffic areas like the kitchen, as they can withstand the wear and tear of daily use without losing their allure. Besides being robust, resin floors are easy to clean, requiring minimal maintenance to keep them looking pristine. Their seamless finish not only adds a modern touch to the space but also enhances the overall home improvement and renovation projects, providing a sleek and elegant backdrop for your kitchen activities.

Durability

One of the primary reasons to opt for a resin floor is its exceptional durability and wear-resistant properties, making it a long-lasting investment for high-traffic areas.

These unique qualities of resin floors mean that they can withstand the daily wear and tear that high-traffic areas often experience. In places like commercial spaces, industrial facilities, or even busy households, the ability of resin floors to resist damage from foot traffic, heavy machinery, and other sources of stress is truly remarkable.

This durability not only ensures that the floor remains visually appealing over time but also minimizes the need for frequent repairs or replacements, ultimately saving homeowners money in the long run. By choosing a resin floor, individuals are not just investing in a surface; they are investing in the future maintenance and resilience of their living or working space.

Easy To Clean

Maintaining a resin floor is hassle-free due to its easy-to-clean nature, requiring simple maintenance and care instructions to keep it looking pristine.

Due to its seamless and non-porous surface, resin floors are exceptionally resistant to stains, making them ideal for households with high foot traffic or messy activities. To preserve the flawless appearance of a resin floor, regular sweeping or vacuuming to remove dust and debris is recommended. Mopping with a mild detergent and water solution will help maintain its shine. Avoid using harsh chemicals or abrasive tools, as they can damage the finish of the floor.

Stylish Appearance

A resin floor offers more than just functionality; it enhances the overall design of a space with its stylish appearance and trendy aesthetic.

By incorporating modern design elements, resin floors play a pivotal role in home decor by seamlessly blending into various interior styles. The sleek finish of resin floors brings a contemporary touch to any room, creating a polished and sophisticated ambiance. Its seamless application adds a sense of continuity to the space, making it visually appealing and aesthetically pleasing. Whether opting for a glossy or matte finish, resin floors elevate the overall aesthetic appeal of a home, adding a touch of luxury and modernity.

What Are The Different Types Of Resin Floors?

There are several types of resin floors available, including epoxy, polyurethane, and methyl methacrylate (MMA) resin, each offering unique features and finishes.

Epoxy resin floors are known for their durability and chemical resistance, making them ideal for industrial settings.

Polyurethane resin floors are versatile and offer excellent UV resistance, making them suitable for outdoor applications.

MMA resin floors are fast-curing and can be installed quickly, making them a popular choice for projects requiring a quick turnaround.

Surface preparation for resin floors typically involves thorough cleaning and profiling to ensure proper adhesion.

Finish options for resin floors range from high-gloss to matte, allowing for customization based on aesthetic preferences and functional needs.

Epoxy Resin

Epoxy resin floors are a popular choice known for their seamless finish, protective qualities, and glossy appearance.

The installation process of epoxy resin floors typically involves thorough surface preparation, application of the epoxy mixture, and a curing period for optimal results. Essential tools for the installation may include a roller, squeegee, mixing paddle, and paintbrush for detailed work. The glossy finish of epoxy resin floors not only enhances the aesthetics of the space but also provides a durable and low-maintenance surface. Applying protective primer coats before the epoxy resin helps to create a strong bond, improve adhesion, and ensure long-lasting performance.

Polyurethane Resin

Polyurethane resin floors are valued for their durability, ease of application, and the protective coat they provide, ensuring long-term benefits for homeowners.

The application process for polyurethane resin floors is relatively straightforward, making it a popular choice for residential spaces. Not only do these floors offer a strong protective coat that can resist stains, spills, and scratches, but they also enhance the overall durability of the floor. With proper installation and maintenance, polyurethane resin floors can last for years, providing a robust and seamless surface that is easy to clean and maintain.

Homeowners investing in polyurethane resin floors can enjoy a beautiful, high-performance flooring solution that stands the test of time.

Methyl Methacrylate (MMA) Resin

Methyl Methacrylate (MMA) resin floors require skilled labor for their installation, involving precise mixing, pouring, and curing processes that are influenced by temperature conditions.

The temperature plays a crucial role in the successful installation of MMA resin floors. Fluctuations in temperature can impact the curing time and overall finish of the floor. It is essential for installers to monitor and control the environmental conditions during the installation process to ensure the optimal performance of the resin.

Extreme temperatures, either too hot or too cold, can lead to problems such as improper curing, bubbling, or cracking on the final surface. Skilled labor is therefore necessary not only for the technical aspects of mixing and pouring but also for managing these temperature variations effectively.

What Are The Steps To Install A Resin Floor In My Kitchen?

- Installing a resin floor in your kitchen involves several key steps, from surface preparation and resin mixing to spreading, leveling, and allowing the floor to harden for a seamless finish.

- Proper surface preparation is crucial as it ensures that the resin adheres securely to the floor, resulting in a durable and long-lasting finish.

- When mixing the resin, make sure to follow the manufacturer’s instructions carefully to achieve the desired consistency.

- Spreading the resin evenly across the surface and using proper tools for leveling helps avoid lumps and bubbles that can compromise the final look.

- Allowing sufficient time for the resin to harden is essential for achieving a smooth and robust surface that can withstand daily wear and tear in a kitchen environment.

Preparing The Surface

Surface preparation is a crucial initial step in installing a resin floor, involving cleaning, ensuring proper ventilation, and maintaining safety during the process.

Proper surface preparation sets the foundation for a successful resin floor application by promoting adhesion and longevity. Utilising specific tools such as industrial-grade vacuums, scrapers, and degreasers helps in removing dirt, grease, and existing coatings.

Thoroughly cleaning the surface eliminates contaminants that could hinder the resin’s ability to bond effectively. Adequate ventilation is essential to disperse fumes from cleaning agents and resin materials, ensuring a safe working environment. Following safety precautions like wearing protective gear, including gloves and masks, further enhances the process.

Mixing The Resin

The mixing of resin is a critical stage in the installation process, requiring precise measurements, suitable temperature conditions, and the use of specific tools for an effective blending process.

Achieving a homogeneous resin mixture is essential for the successful application of resin floors. Properly mixed resin ensures optimal chemical reactions, leading to a durable and visually appealing finished product. Maintaining the recommended temperature range is crucial to prevent premature curing or extended drying times. Utilising tools like mixing sticks or paddle attachments on drills aids in achieving a uniform blend. Following a step-by-step process, such as gradually adding resin to the hardener while stirring continuously, helps avoid air bubbles and inconsistencies. Ultimately, the accuracy of resin mixing directly impacts the quality and longevity of the resin floor.

Applying The Resin

The application of resin entails pouring and spreading the mixture evenly, a task that often requires skilled labour to ensure a uniform and protective coating across the floor.

The process of applying resin involves meticulous attention to detail, starting with the careful preparation of the surface to create an ideal foundation for the resin application. Skilled labour plays a crucial role in this stage, as they are adept at assessing the surface condition and making any necessary repairs or adjustments before commencing with the pouring and spreading of the resin mixture.

Once the surface is primed, the resin is poured strategically and spread methodically to achieve a seamless finish, eliminating any air bubbles or uneven patches. This careful technique ensures that the resin cures uniformly, creating a durable and attractive surface.

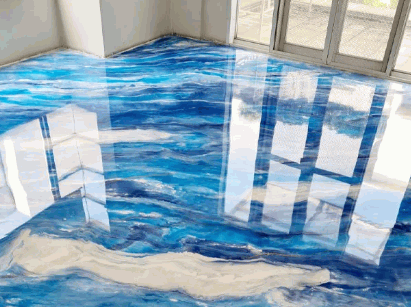

Adding Decorative Elements (Optional)

For a personalised touch, homeowners can choose to incorporate decorative elements into the resin floor, such as custom designs or a variety of colour options to enhance the overall aesthetics.

These decorative elements offer a myriad of design choices, ranging from intricate patterns to abstract shapes, allowing individuals to create a floor that truly reflects their style and personality.

By carefully selecting complementary colours or contrasting hues, the resin floor can be transformed into a stunning focal point in any room.

Incorporating elements like metallic flakes, glitter, or even embedded objects can add depth and texture, elevating the visual appeal of the floor and making it a true work of art.

Sealing The Floor

Sealing the resin floor with a protective coat or primer is essential to ensure longevity and durability, providing the finishing touches necessary for a polished and seamless surface.

By applying a protective coat, the resin floor is shielded from wear and tear, stains, and chemicals, ensuring it maintains its aesthetic appeal for years to come. The primer enhances adhesion, promoting a strong bond between the resin and the underlying substrate, preventing delamination, and promoting structural integrity. This extra layer of protection not only enhances the durability of the floor but also makes maintenance easier, as the surface becomes more resistant to scratches and abrasions, saving time and costs in the long run.

What Tools And Materials Do I Need For The Installation?

To install a resin floor, you will require specific tools and materials such as adhesives, sealants, and protective coats, which are essential for the project and represent a valuable investment in your home.

Adhesives are crucial in securing the resin material to the existing concrete or substrate, ensuring a strong bond that will withstand daily wear and tear.

Sealants play a vital role in protecting the surface from stains, water damage, and UV exposure, extending the longevity of your resin floor.

Protective coats provide an additional layer of durability, enhancing the overall strength and resistance to scratches and impacts, making your investment in a resin floor a long-lasting solution for your home renovation project.

What Are The Maintenance Tips For A Resin Floor?

Effective maintenance of a resin floor involves following key tips such as regular cleaning, prompt repairs, and using proper care instructions to preserve its quality and appearance.

Regular cleaning is essential in preventing dirt and debris from building upon the resin floor surface, which could lead to discolouration or damage over time. Promptly addressing any repairs or damages, such as cracks or chipped areas, can prevent further deterioration and ensure the longevity of the floor. Adhering to care instructions provided by the manufacturer will also help in maintaining the quality and finish of the resin floor.

By following these maintenance tips diligently, you can save time and effort in caring for your resin floor and keep it looking fresh and well-maintained for years to come.

Regular Cleaning

Regular cleaning is essential for maintaining the pristine condition of a resin floor, following specific care instructions to ensure its longevity within a household environment.

By incorporating a consistent cleaning routine, homeowners can not only preserve the aesthetic appeal of their resin floors but also prevent dirt and grime buildup that can lead to discolouration and deterioration over time.

To effectively care for resin floors, it is recommended to sweep or vacuum regularly to remove loose debris and dust. Using a mild detergent and warm water solution for mopping, followed by thorough rinsing and drying, can help maintain the shine and structural integrity of the resin surface.

Avoid Harsh Chemicals

To protect the integrity of a resin floor, it is crucial to avoid harsh chemicals during maintenance, as they can damage the surface and compromise its longevity.

Instead of harsh chemicals, homeowners can opt for gentle cleaning solutions such as a mixture of warm water and mild soap.

Regularly sweeping or vacuuming the floor to remove dirt and debris is also essential in preserving its quality.

Placing protective mats at entryways can prevent abrasive particles from scratching the resin surface.

By adopting these alternative cleaning methods and protective measures, homeowners can ensure that their resin floors remain in top condition for years to come.

Repair Any Damages Promptly

Timely repairs are crucial in addressing any damages on a resin floor, ensuring that maintenance tasks are completed effectively to preserve the floor’s integrity and appearance.

By promptly attending to damages on resin floors, you can prevent further deterioration and extend the longevity of the flooring. Common damages like scratches, chips, or discolouration can be effectively addressed through repair techniques such as sanding, filling, and recoating. It is essential to prioritise project completion when dealing with these repairs, as procrastination can lead to more extensive damage and higher repair costs.

Regular inspection and quick action are key practices in maintaining the pristine appearance of resin floors.

Protect The Floor From Heavy Objects

Preventing heavy objects from impacting the resin floor is essential for its maintenance, as protecting the surface from undue stress helps in preserving its quality and appearance.

Placing protective pads or cushions under furniture legs can distribute weight evenly and reduce the risk of indentation marks on the resin flooring. Using floor mats near entryways and high-traffic areas can prevent dirt and debris from scratching the surface. Regularly sweeping and mopping the floor with a gentle cleanser not only keeps it clean but also eliminates abrasive particles that could cause damage. It’s also advisable to avoid dragging heavy items across the floor to minimise scratches and scuffs.

Reapply Sealant As Needed

Regularly reapplying sealant to the resin floor is essential for maintaining its protective coat and ensuring long-lasting durability, marking the completion of a crucial aspect of the maintenance routine.

This practice helps to safeguard the floor against wear and tear, spills, and stains by creating a barrier that enhances its resilience.

The frequency of sealant reapplication depends on factors such as foot traffic and the type of sealant used. Generally, it is advisable to reapply sealant every 1-3 years to uphold the floor’s protective qualities.

Before resealing, ensure the floor is thoroughly cleaned and dried to guarantee optimal adhesion. A well-maintained resin floor not only looks great but also contributes to a safer and more hygienic environ